Using Electrolyzers to Produce Renewable Hydrogen

Connor Dolan

By Quailan Homann

Hydrogen is gaining popularity across the world as a source of clean energy with applications in transportation, stationary power, aviation, shipping, and more. When used as a fuel for a fuel cell system, the only by-products of the reaction are electricity, heat, and water, demonstrating the dramatic potential for emissions reductions across market sectors. In addition to decarbonizing these end-use applications, there is also much work underway to reduce the carbon intensity of hydrogen production itself. These methods include producing hydrogen from biomass or biomethane, as well as using renewable electricity from wind or solar power to power an electrolyzer. Electrolysis is the process of using electricity to split water into its component parts of hydrogen and oxygen. That hydrogen can then be stored for later use as fuel in a fuel cell vehicle, to power a stationary fuel cell system, or for power-to-gas applications. Using hydrogen to store excess power generated from renewables is showing great potential. According to the International Renewable Energy Agency, renewable hydrogen produced from electrolysis is projected to grow rapidly, citing a current growth trend from megawatt to gigawatt scale in Europe.

How electrolyzers work

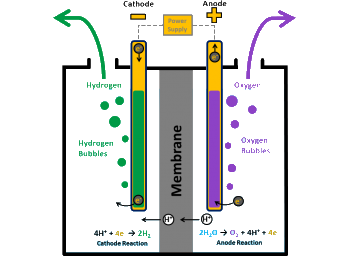

Electrolysis works like a fuel cell in reverse, which has an anode and a cathode separated by an electrolyte. In fact, some fuel cells can operate in reverse to produce hydrogen. By running an electrical current through water, the membrane and electrolyte can separate the water into hydrogen and oxygen.

Polymer electrolyte membrane (PEM) electrolyzer operation. Source: US Department of Energy (DOE)

The most common types of electrolyzers utilize polymer electrolyte, alkaline, or solid oxide membranes as their core components. These electrolyzer types vary in chemical composition and temperature, making them applicable in different environments.

Applications

The electricity can be supplied from any source, but the most promising option to eliminate carbon emissions is the use of renewable energy such as solar and wind power. Using an electrolyzer in conjunction with renewable energy creates renewable hydrogen that is sourced from and transforms back into water through its lifecycle, offering a true zero emissions source of fuel and power to the end user.

Governments, industry, and environmental organizations are interested in using electrolysis to store excess renewable energy resulting from the “duck curve.” The duck curve is a phenomenon resulting in a surplus of energy during the day when solar power generation peaks, but demand is at its lowest point. During the evening hours when the sun sets and solar is no longer available, power demand peaks. By converting the surplus power to hydrogen (power-to-hydrogen), power companies can shift the use of renewable energy from the daytime to the night. This aids in solving both the issue of excess power generation and the increased demand at times when renewables are at a shortage.

Duck curve example. Source: California Independent System Operator (CAISO)

Examples

Below are examples of electrolysis deployment across the world. While the European Union has taken the lead on renewable-powered electrolyzers, many other countries have displayed an interest in growing their electrolyzer usage.

Denmark

In Denmark, electrolyzer manufacturer and FCHEA member Nel Hydrogen, Danish energy company Ørsted, and other industry partners received funding for a two-megawatt electrolysis plant powered by offshore wind turbines. The Avedøre, Denmark-based plant is planned to produce around 600 kilograms of hydrogen a day for fuel cell buses, lorries, and taxis.

Avedøre Power Station on Avedøre Holme. Source: Ørsted

Nel Hydrogen is also working to establish a 20-megawatt electrolyzer at a Shell oil refinery in Fredericia, Denmark. The electrolyzer will be ready to increase capacity to one-gigawatt in the future.

Netherlands

The Netherlands Port of Rotterdam is partnering with BP and Nouryon to produce wind-sourced renewable hydrogen.

Norway

Nel has received grants to develop advanced alkaline electrolyzers in Norway, and a one-gigawatt per year manufacturing plant in Herøya, Norway.

South Africa

In South Africa, FCHEA members Plug Power and Anglo American are developing hydrogen systems for a fuel cell-powered ultra-heavy-duty mining truck. Nel will be supplying a 3.5-megawatt solar-powered electrolyzer to produce hydrogen for the truck.

Australia

The Australian Renewable Energy Agency is looking into funding large scale electrolyzer projects that utilize renewable energy.

Canada

Quebec has deployed an electrolyzer connected to a hydrogen refueling station.

Germany

Germany’s “Silver Frog” project is a proposal to establish a two-gigawatt solar plant to power electrolyzers for hydrogen.

France

South-East France has the haulage project H2Haul with FCHEA member Air Liquide that intends to use electrolyzers.

Switzerland

Hyundai Hydrogen Mobility has a two-megawatt electrolyzer plant in Switzerland to supply hydrogen for fuel cell trucks.

USA

In Ohio, the US DOE has funded an advanced program that uses a light water nuclear reactor in conjunction with an electrolyzer to produce hydrogen.

In Hawaii, the US Air Force is using an electrolyzer to produce hydrogen for an aircraft tow tractor.

Conclusion

Hydrogen production via electrolysis offers an opportunity to store renewable energy. By decarbonizing hydrogen, companies are further able to decarbonize sectors such as energy and steel and provide lower well-to-wheel emissions for transportation. As electrolysis capacity grows, so will the availability of green hydrogen fuel and energy storage, a commercially-viable solution and alternative to fossil fuels.